Product Description:

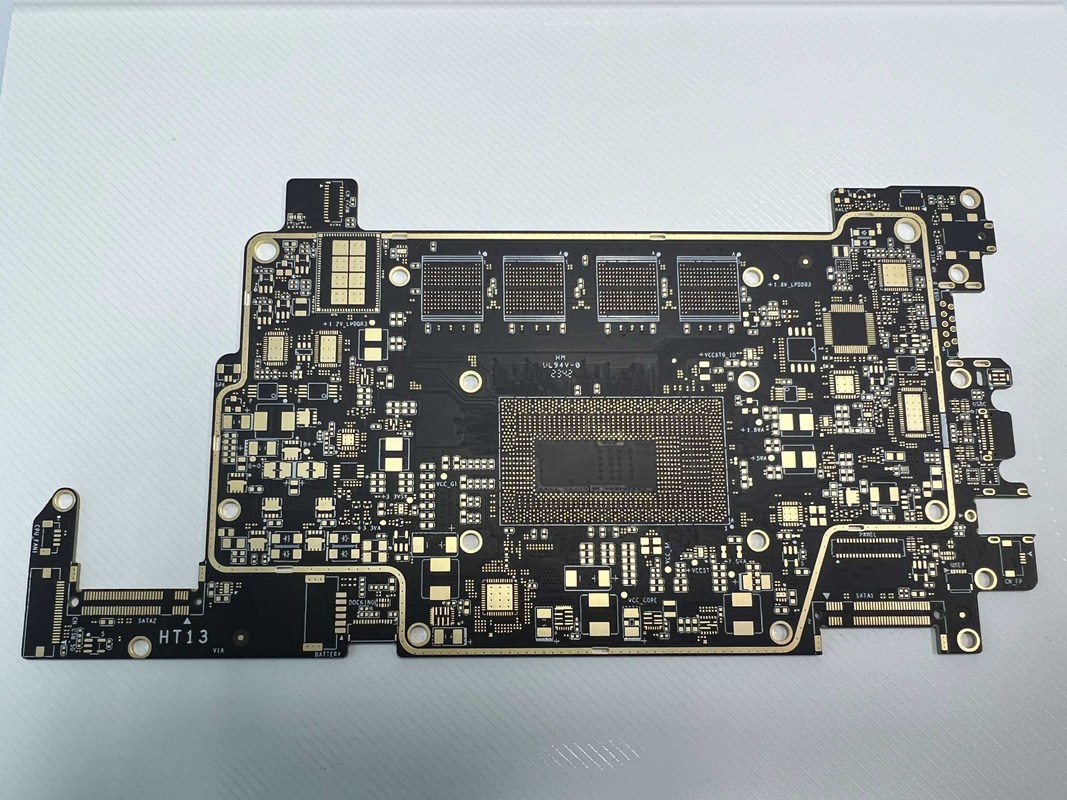

The HDI PCB Board is a cutting-edge product designed to meet the demands of high-density interconnection applications. With advanced features and specifications, this PCB board is ideal for a wide range of industries, including telecommunications, medical devices, aerospace, and more.

One of the standout features of the HDI PCB Board is its Immersion Silver coating, which provides excellent conductivity and corrosion resistance. This coating ensures reliable performance and longevity, making it suitable for critical applications where performance is paramount.

Measuring at a thickness of 1.6mm with a tolerance of ±10%, the HDI PCB Board offers a sturdy and durable construction that can withstand rigorous operating conditions. This ensures that the PCB board maintains its structural integrity and electrical performance over an extended period.

The surface finish options for the HDI PCB Board include HASL, ENIG, OSP, Immersion Silver, Immersion Tin, and more. These surface finishes provide versatility in terms of compatibility with various components and soldering methods, meeting the diverse needs of different applications.

With a vias aspect ratio of 16:1, the HDI PCB Board offers exceptional routing flexibility and signal integrity. This high aspect ratio allows for the efficient routing of signals across multiple layers, minimizing signal loss and ensuring optimal performance in complex circuit designs.

For enhanced visibility and branding, the HDI PCB Board supports silkscreen printing in colors such as white, black, yellow, and more. This customization option allows for clear labeling of components, connectors, and other critical information on the PCB board, facilitating ease of assembly and troubleshooting.

In conclusion, the HDI PCB Board is a premium solution for high-density interconnection applications that require superior performance, reliability, and versatility. With its Immersion Silver coating, precise thickness, multiple surface finish options, high vias aspect ratio, and customizable silkscreen printing, this PCB board is well-equipped to meet the demanding requirements of modern technologies.

Features:

-

Product Name: HDI PCB Board

-

Surface Mount Technology: Available

-

Feature: Immersion Silver

-

Aspect Ratio: 10:1

-

Pcb Assembly Process: SMT THT DIP SMT PCB Assembly

-

Min. Solder Mask Bridge: 0.075mm

Technical Parameters:

|

Surface Finish:

|

HASL, ENIG, OSP, Immersion Silver, Immersion Tin, Etc.

|

|

Glass Epoxy:

|

RO4350B Tg280℃, Er<3.48, Rogers Corp.

|

|

Surface Mount Technology:

|

Available

|

|

Mini Holes:

|

0.1mm

|

|

Vias Aspect Ratio:

|

16:1

|

|

Copper Thickness:

|

0.5oz-6oz

|

|

Finished Copper Thickness:

|

1oz

|

|

Silkscreen:

|

White, Black, Yellow, Etc.

|

|

Feature:

|

Immersion Silver

|

Applications:

Product Application Occasions and Scenarios for the HDI PCB Board:

The High Density Interconnector (HDI) PCB boards are widely used in various electronics applications due to their superior design and performance attributes. With a thickness of 1.6mm, these PCB boards are ideal for applications requiring high density interconnections and miniaturization.

One common application scenario for HDI PCB boards is in DDR4 PCB designs, where the mini holes of 0.1mm and surface finishes such as HASL, ENIG, OSP, Immersion Silver, and Immersion Tin play a crucial role in ensuring reliable connections and signal integrity.

These high-density PCB boards are commonly used in scenarios where space constraints are a concern, such as in mobile devices, IoT devices, and other compact electronics. The ±10% thickness tolerance ensures consistency in manufacturing and assembly processes, making HDI PCB boards a reliable choice for demanding applications.

Furthermore, the minimum solder mask bridge of 0.075mm allows for precise soldering and assembly, making HDI PCB boards suitable for high-speed and high-frequency applications where signal accuracy is critical.

In summary, the High Density Interconnector (HDI) PCB boards are versatile solutions for a wide range of applications, including DDR4 PCB designs and other high-density interconnection scenarios. With their advanced design features and materials, HDI PCB boards offer reliability, performance, and scalability for modern electronics applications.

Customization:

Product Customization Services for High Speed HDI PCB Manufacturing:

- Glass Epoxy: RO4350B Tg280℃, Er<3.48, Rogers Corp.

- Thickness: 1.6mm, ±10%

- Vias Aspect Ratio: 16:1

- Min. Solder Mask Bridge: 0.075mm

- Surface Mount Technology: Available

Support and Services:

The Product Technical Support and Services for the HDI PCB Board product include:

- Expert technical support for any inquiries related to the HDI PCB Board product.

- Assistance with product installation, setup, and troubleshooting.

- Documentation and resources for proper usage and maintenance of the HDI PCB Board.

- Training services for users to enhance their understanding of the product and its capabilities.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!