Product Description:

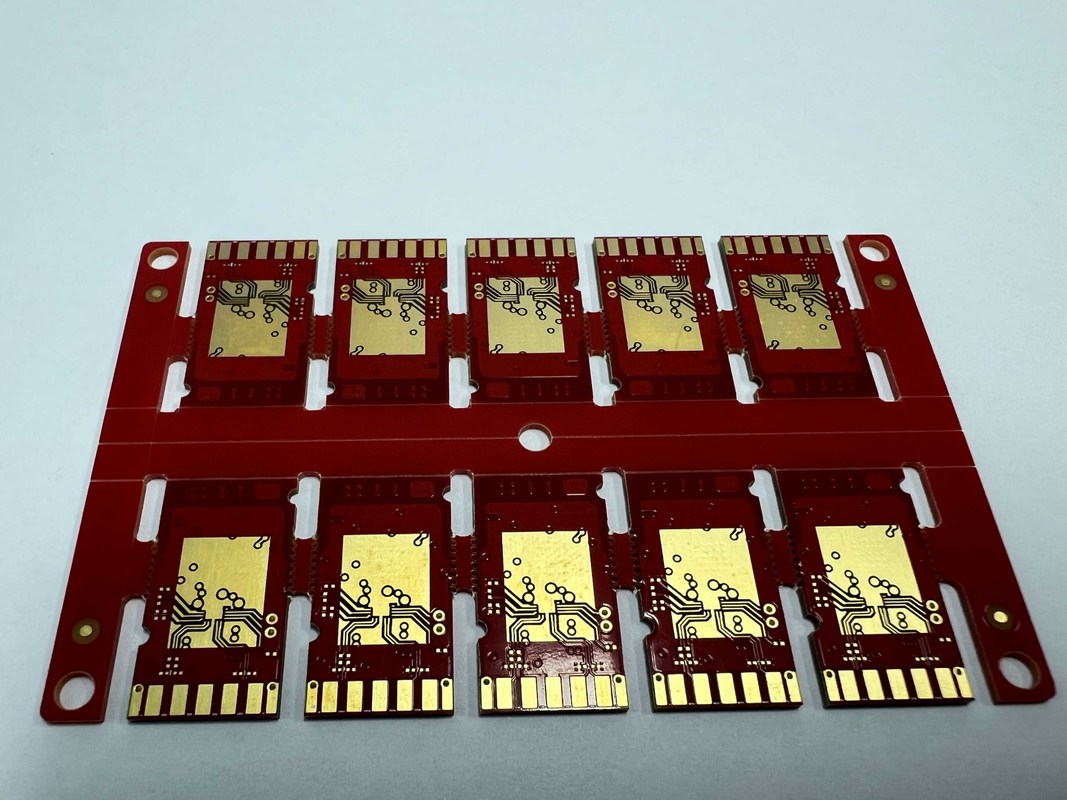

The HDI PCB Board is a cutting-edge product that incorporates advanced technology to meet the demands of high-speed electronic applications. With its Vip Process, this PCB board offers superior performance and reliability, making it ideal for a wide range of industries.

Featuring a thickness of 1.6mm with a tolerance of ±10%, the HDI PCB Board provides excellent durability and stability, ensuring consistent performance in various operating conditions. This thickness specification is well-suited for high-density interconnector applications, where precision and reliability are crucial.

When it comes to aesthetics and functionality, the HDI PCB Board offers a customizable silkscreen in a variety of colors such as white, black, yellow, and more. This feature allows for easy identification and organization of components, enhancing the overall user experience and efficiency of the PCB board.

The HDI PCB Board is specifically designed for high-density interconnect applications, making it an ideal choice for projects that require intricate routing and compact designs. Its innovative construction and materials, such as Glass Epoxy RO4350B Tg280℃ with Er<3.48 from Rogers Corp., ensure high performance and reliability in demanding environments.

Whether you are working on a high-speed PCB project or require an HD SDI converter, the HDI PCB Board is equipped to deliver exceptional results. Its advanced features and quality construction make it a reliable and efficient solution for a wide range of electronic applications.

Features:

-

Product Name: HDI PCB Board

-

VIP Process: Yes

-

Finished Copper Thickness: 1oz

-

Min. Solder Mask Bridge: 0.075mm

-

PCB Assembly Process: SMT THT DIP SMT PCB Assembly

-

Surface Finish: HASL, ENIG, OSP, Immersion Silver, Immersion Tin, Etc.

Technical Parameters:

|

Silkscreen

|

White, Black, Yellow, Etc.

|

|

Feature

|

Immersion Silver

|

|

Mini Holes

|

0.1mm

|

|

Thickness

|

1.6mm, ±10%

|

|

Glass Epoxy

|

RO4350B Tg280℃, Er<3.48, Rogers Corp.

|

|

Surface Mount Technology

|

Available

|

|

Vip Process

|

Yes

|

|

Aspect Ratio

|

10:1

|

|

Surface Finish

|

HASL, ENIG, OSP, Immersion Silver, Immersion Tin, Etc.

|

|

Key Words

|

High Density Interconnector

|

Applications:

HDI Printed Circuit Boards (PCBs) are a specialized type of circuit board that offer a high level of performance and efficiency due to their unique design features. One key attribute of HDI PCB Boards is the mini holes, which typically have a diameter of 0.1mm. These mini holes allow for a higher density of interconnections, making HDI PCBs ideal for applications where space is limited and a large number of components need to be densely packed.

Another important attribute of HDI PCB Boards is the vias aspect ratio, which is typically 16:1. This aspect ratio allows for the creation of smaller, more compact vias, further contributing to the overall high density of interconnections on the board.

Manufacturing HDI PCBs requires specialized processes and techniques to achieve the desired level of performance and reliability. Vip (Vertical Interconnect Process) is a common process used in the manufacturing of HDI PCBs, allowing for the creation of complex, multi-layered interconnections that meet the high demands of modern electronic devices.

The thickness of HDI PCB Boards is typically 1.6mm, with a tolerance of ±10%. This standard thickness ensures compatibility with industry-standard components and allows for easy integration into a wide range of electronic devices.

Overall, HDI PCB Boards are well-suited for a variety of applications and scenarios that require high-density interconnectivity, such as advanced electronics, telecommunications equipment, medical devices, aerospace systems, and more. Their compact size, high performance, and reliable interconnections make them a popular choice for manufacturers looking to optimize space and functionality in their products.

In conclusion, HDI PCB Boards offer a range of benefits for various industries and applications, making them a versatile and reliable choice for high-density interconnector needs. Whether used in consumer electronics, automotive systems, industrial equipment, or other advanced technologies, HDI PCBs provide a solid foundation for efficient and high-performance electronic devices.

Customization:

Product Customization Services for High Speed PCB, DDR4 PCB, HDI PCB Manufacturing:

Surface Finish: HASL, ENIG, OSP, Immersion Silver, Immersion Tin, etc.

Surface Mount Technology: Available

Min. Solder Mask Bridge: 0.075mm

Thickness: 1.6mm, ±10%

Glass Epoxy: RO4350B Tg280℃, Er<3.48, Rogers Corp.

Support and Services:

The Product Technical Support and Services for the HDI PCB Board product include:

- Comprehensive troubleshooting assistance for any technical issues related to the HDI PCB Board.

- Guidance on proper installation and usage of the HDI PCB Board to ensure optimal performance.

- Regular software updates and firmware upgrades to enhance the functionality and security of the HDI PCB Board.

- Warranty coverage and repair services for any manufacturing defects or malfunctions of the HDI PCB Board.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!